Post by vernon240 on Dec 5, 2012 10:46:00 GMT

Yea Owen, you just keep drinking the strong stuff!

OK, so my shell is at the soda blasters and as the place, 'Soda Blast' is only 6 miles from location in Sevenoaks, I was keen to take a look and I was made more than welcome.

The chamber itself is essentially a huge room where one side of the room opens to let cars in.

Here's may car in place with the large door at the end closed:

They use a number of grades of soda media, but the first one is like talcum powder, maybe slightly coarser, but not much, and nothing like sand. The idea is that the soda crystals explode on contact with the substrate, removing the paint in the process. Apparently it can work on really delicate items down to around 10psi.

When I arrived, the engine bat and underneath had been done with both the fine grade to remove the paint, and then a courser grade to remove rust and key the surface.

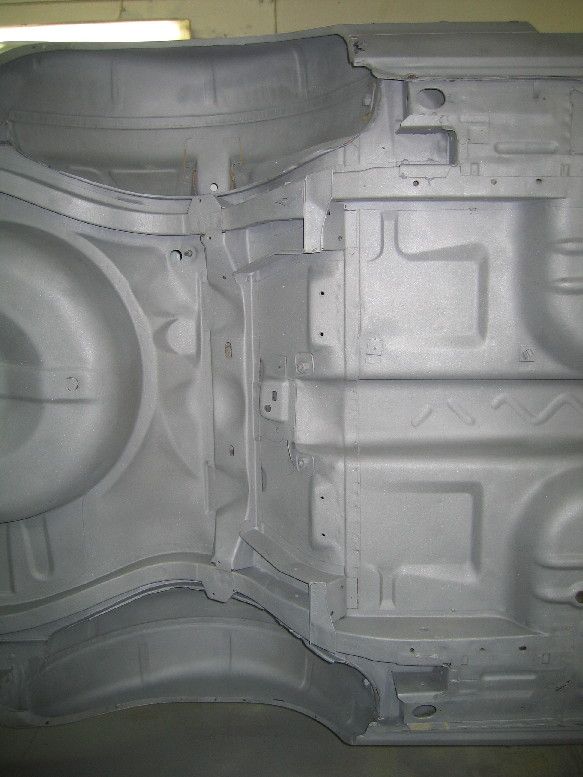

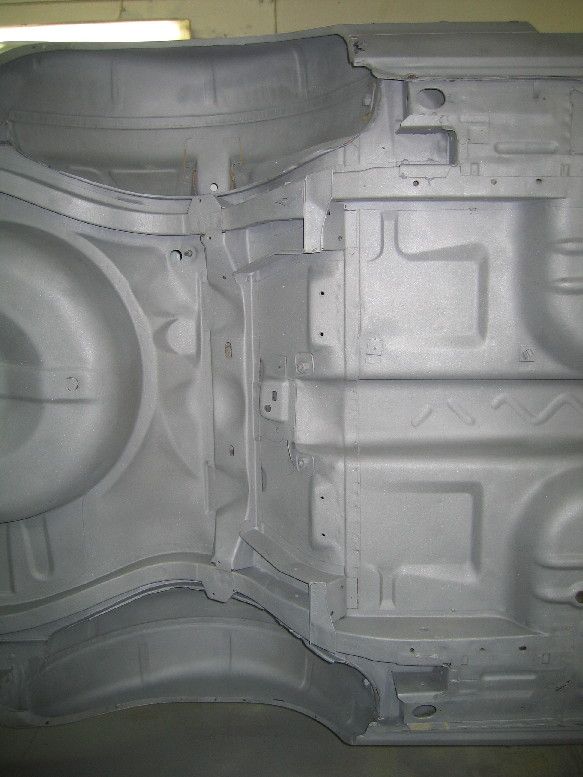

When they rolled the car over, this is what I saw:

It all looks pretty good and overall, no real surprises!

Here, looking at the front, it all looks good. The strut tops need work, but on the whole, pretty good, Note how the soda gets into the front cross member very well. Not 100% but pretty close.

Looking into the engine bay again, it's all good. Two repairs need to be re-done right where the bumper irons bolt to, while the battery tray, while fairly solid, is far too pitted to be used again, as it's pin holed over a large area.

Working our way back, the bulkhead is good, but where the bulkhead overlaps the floors there are issues, as with the A post bottoms, but nothing unexpected here. Quite a few dents in the chassis rails though!

Mid floor, all looking good except for the double skinned area by the forward rear spring mounts. A common capri weak spot, but pretty d**n good for a car of this age.

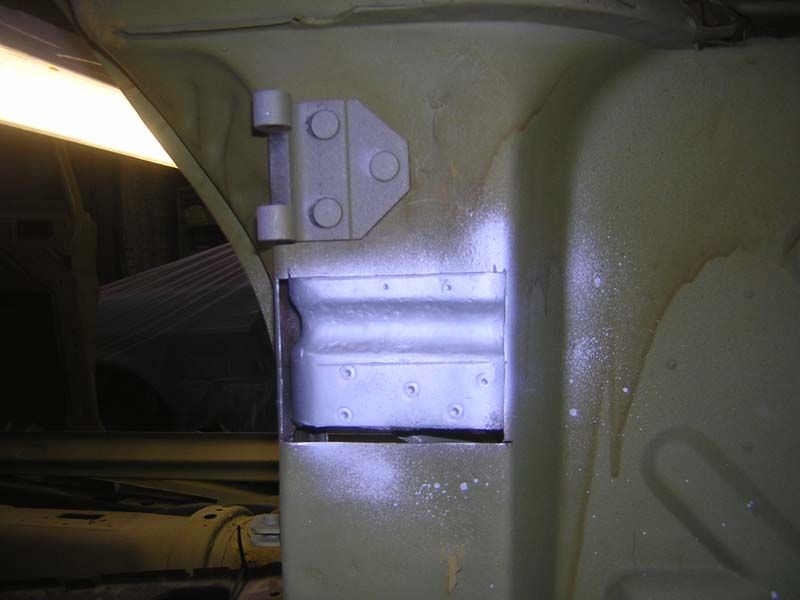

Here's a close up of the drivers side area. The passenger side had not been repaired, but this side had a plate. My 2 year old daughter has just discovered paper and scissors and will quite happily cut out shapes reminiscent of this style!

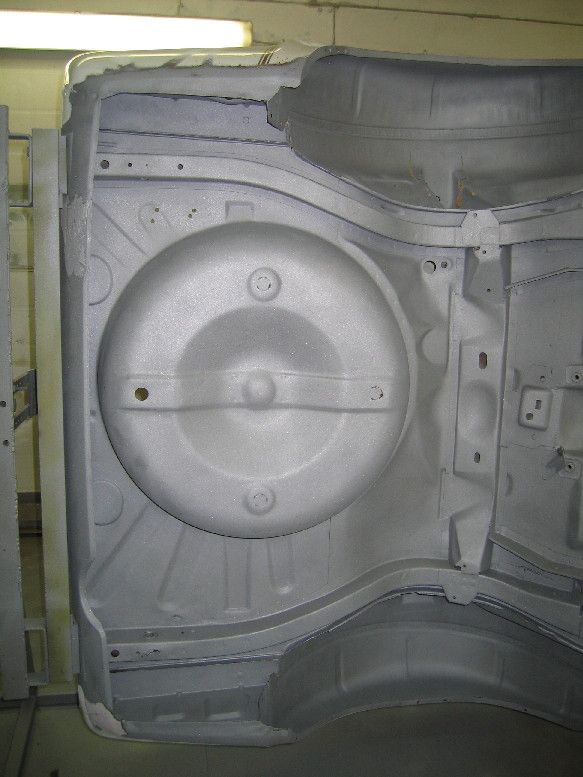

Further back and looking good. Especially pleased with the wheel arches and wheel wells! They are neigh on perfect! the arch lips will need work, however.

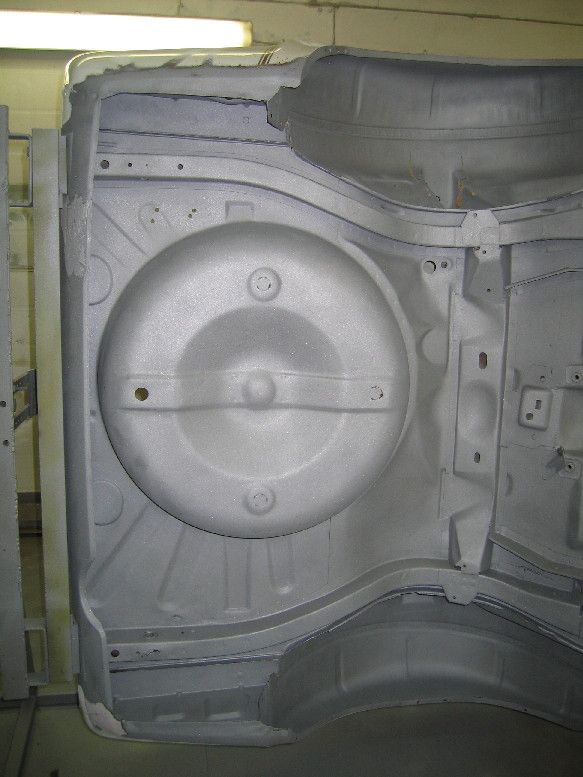

Rear end. It's not uncommon for the spare wheel well to disintegrate to nothing, so once again, very pleased. Issues here are with the far ends of the chassis rails. The drivers side (top) is swelling, so will need to be replaced at it's far extremity, while the passenger side one is actually holed through the out layer of steel, so just a little more advanced.

You can also see some filler in the rear valance. This covers a plate where an extra exhaust cut out was made. A common conversion on capris to give it that muscle car dual exhaust look.

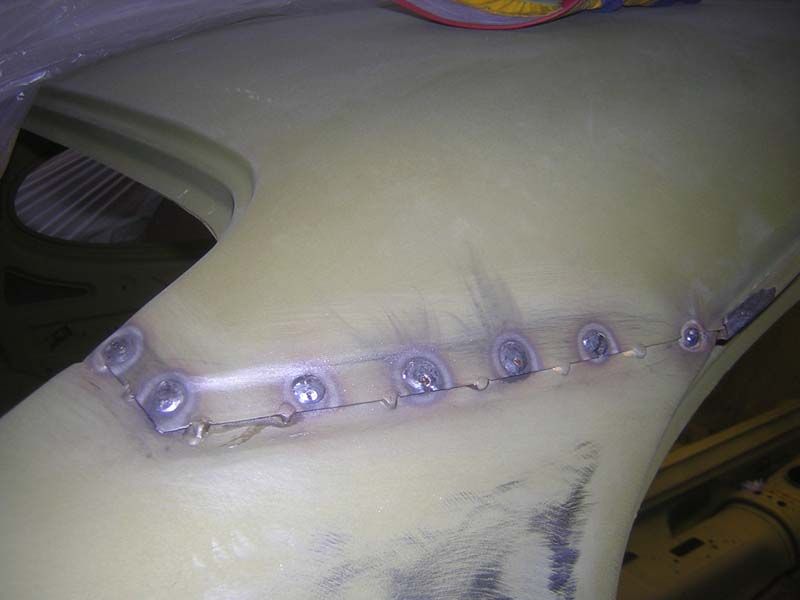

Here you can see the plate, plus an unexpected issue. The rear valance is a single piece of sheet steel. You can see here that the outer panel appears to be neatly stitch welded to the remains of an inner panel, while there appears to be another panel in there as well. Needs investigation. I gave a spare rear panel to Soda Blasters to blast. It looks like I'll need it! You can also see the keyed surface the more abrasive media leaves

Finally, I donned a dust mask and video'd some of the process.

This shows that they try not to hit the panel at 90 degrees and try and use a very subtle angle. This was the initial process where the very fine soda is used to clean off paint. Straight after this process I touched the panel. Still as cold as the rest of the car.

Here's the panel right after the video session. Note the difference between the soda blasted panel and the area below that has also been subjected to the harsher media for keying the surface and rust removal. The panel looks and feels like it had just come from a press. Wheel arches this sound are a real rarity.

a close up of the area showing no paint, but rust around the holes for the fake vents.

The next harsher media will remove these and take care of the rust. This shows how Soda can take paint from fiber glass without damaging the gel coat beneath, so they will be doing my rear spoiler as well.

Thats all for now, but the shell should be finished at Soda Blast by next Monday.

OK, so my shell is at the soda blasters and as the place, 'Soda Blast' is only 6 miles from location in Sevenoaks, I was keen to take a look and I was made more than welcome.

The chamber itself is essentially a huge room where one side of the room opens to let cars in.

Here's may car in place with the large door at the end closed:

They use a number of grades of soda media, but the first one is like talcum powder, maybe slightly coarser, but not much, and nothing like sand. The idea is that the soda crystals explode on contact with the substrate, removing the paint in the process. Apparently it can work on really delicate items down to around 10psi.

When I arrived, the engine bat and underneath had been done with both the fine grade to remove the paint, and then a courser grade to remove rust and key the surface.

When they rolled the car over, this is what I saw:

It all looks pretty good and overall, no real surprises!

Here, looking at the front, it all looks good. The strut tops need work, but on the whole, pretty good, Note how the soda gets into the front cross member very well. Not 100% but pretty close.

Looking into the engine bay again, it's all good. Two repairs need to be re-done right where the bumper irons bolt to, while the battery tray, while fairly solid, is far too pitted to be used again, as it's pin holed over a large area.

Working our way back, the bulkhead is good, but where the bulkhead overlaps the floors there are issues, as with the A post bottoms, but nothing unexpected here. Quite a few dents in the chassis rails though!

Mid floor, all looking good except for the double skinned area by the forward rear spring mounts. A common capri weak spot, but pretty d**n good for a car of this age.

Here's a close up of the drivers side area. The passenger side had not been repaired, but this side had a plate. My 2 year old daughter has just discovered paper and scissors and will quite happily cut out shapes reminiscent of this style!

Further back and looking good. Especially pleased with the wheel arches and wheel wells! They are neigh on perfect! the arch lips will need work, however.

Rear end. It's not uncommon for the spare wheel well to disintegrate to nothing, so once again, very pleased. Issues here are with the far ends of the chassis rails. The drivers side (top) is swelling, so will need to be replaced at it's far extremity, while the passenger side one is actually holed through the out layer of steel, so just a little more advanced.

You can also see some filler in the rear valance. This covers a plate where an extra exhaust cut out was made. A common conversion on capris to give it that muscle car dual exhaust look.

Here you can see the plate, plus an unexpected issue. The rear valance is a single piece of sheet steel. You can see here that the outer panel appears to be neatly stitch welded to the remains of an inner panel, while there appears to be another panel in there as well. Needs investigation. I gave a spare rear panel to Soda Blasters to blast. It looks like I'll need it! You can also see the keyed surface the more abrasive media leaves

Finally, I donned a dust mask and video'd some of the process.

This shows that they try not to hit the panel at 90 degrees and try and use a very subtle angle. This was the initial process where the very fine soda is used to clean off paint. Straight after this process I touched the panel. Still as cold as the rest of the car.

Here's the panel right after the video session. Note the difference between the soda blasted panel and the area below that has also been subjected to the harsher media for keying the surface and rust removal. The panel looks and feels like it had just come from a press. Wheel arches this sound are a real rarity.

a close up of the area showing no paint, but rust around the holes for the fake vents.

The next harsher media will remove these and take care of the rust. This shows how Soda can take paint from fiber glass without damaging the gel coat beneath, so they will be doing my rear spoiler as well.

Thats all for now, but the shell should be finished at Soda Blast by next Monday.

;D ;D

;D ;D